Technical characteristics

Determine the complete lattice orientation of a single crystal

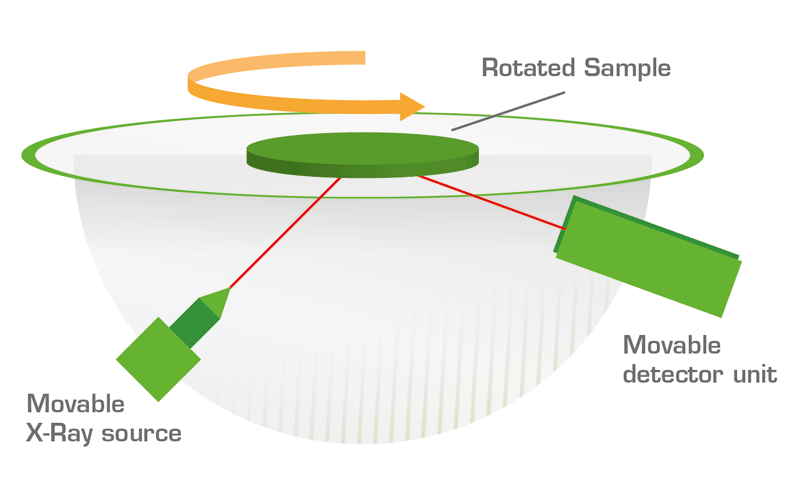

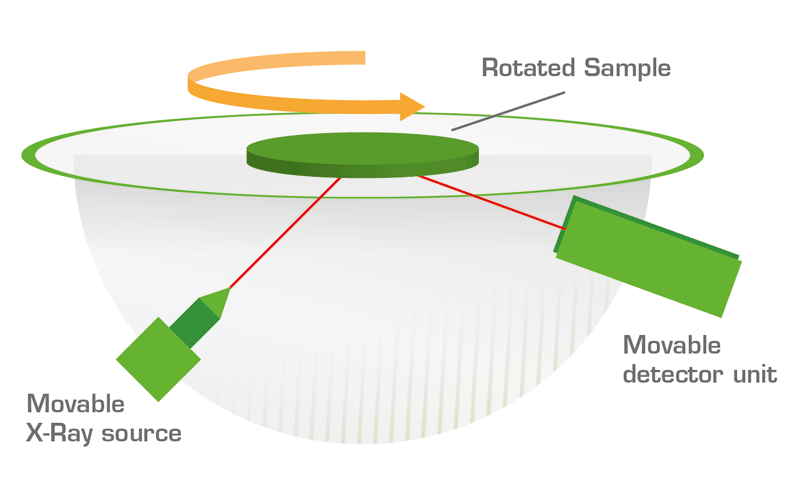

Ultra high speed crystal positioning measurement using Omega scanning method

Determination of arbitrary unknown orientation of cubic crystals

Specially designed for azimuth setting and marking in lattice direction

Air cooled X-ray tube, no need for water cooling

Suitable for research and production quality control

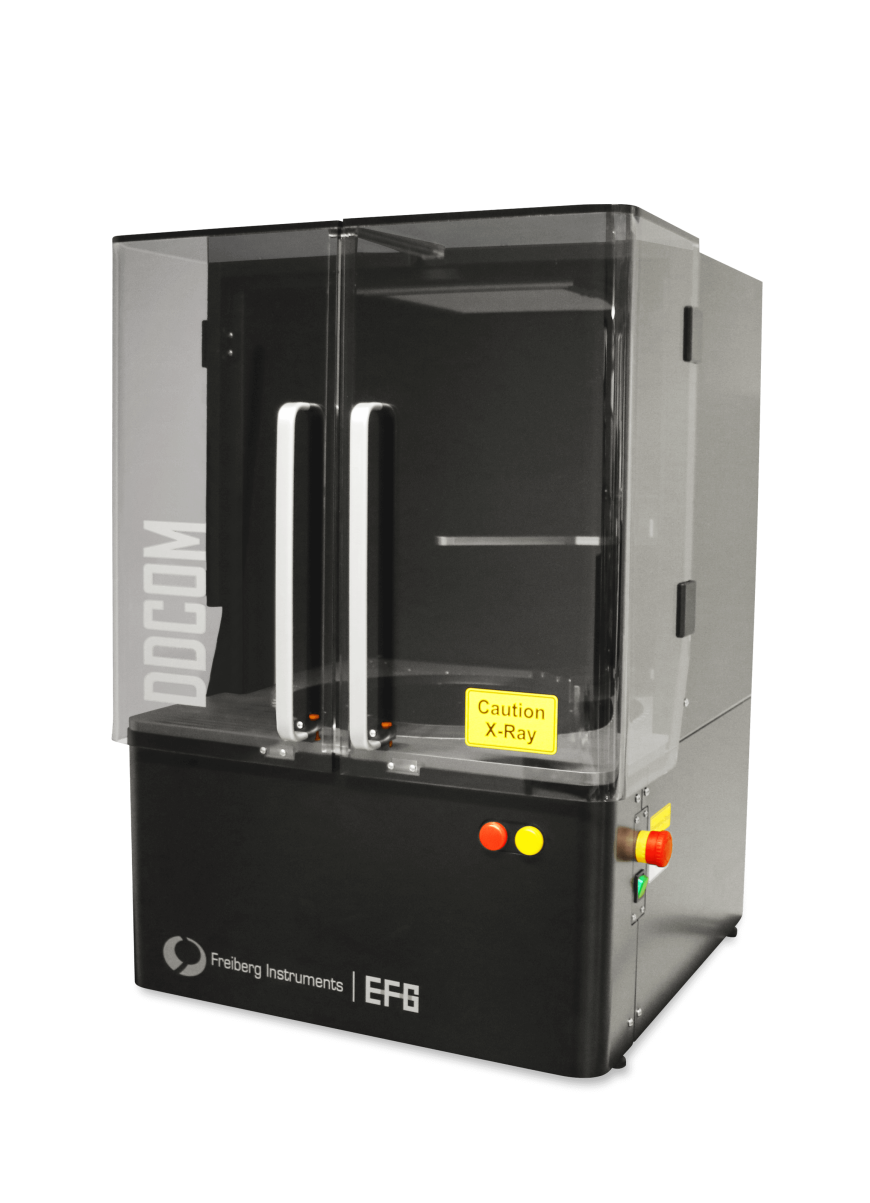

X-ray single crystal directional instrument

All desired crystal orientation parameters are captured in one rotation within 5 seconds

Examples of Measurable Materials

Ø Cube/Any unknown direction: Si, Ge, GaAs, GaP, InP

Ø Cubic/Special orientation: Ag, Au, Ni, Pt, GaSb, InAs, InSb, AlSb, ZnTe, CdTe, SiC3C, PbS, PbTe, SnTe, MgO, LiF, MgAl2O4, SrTiO3, LaTiO3

Ø Square: MgF2, TiO2, SrLaAlO4

Ø Hexagonal/triangular: SiC 2H, 4H, 6H, 15R, GaN, ZnO, LiNbO3, SiO2 (quartz), Al2O3 (sapphire), GaPO4, La3Ga5SiO14

Ø Orthorhombic crystal system: Mg2SiO4 NdGaO3

Ø Further material selection can be made according to customer requirements

X-ray single crystal directional instrument

Application of DDCOM

Marking and measurement of plane direction

During the injection and lithography process of wafers, flat or grooved surfaces are required as positioning markers. During the cutting process, the chip must correctly align with the lattice planes on the quasi crystal wafer that are easy to cut. Therefore, it is crucial to check the position of the plane or gap.

To determine the position of a plane or gap, it is necessary to measure the components within the plane. Due to the Omega scanning method being able to determine the complete crystal orientation in a single measurement, it is possible to directly identify units or gaps in the plane direction or inspection direction.

DDCOM can convert any plane direction to a specific position specified by the user by rotating the turntable. When it is necessary to define the plane direction, this can greatly simplify the process of applying markers to specific plane directions.