automaticMapping face scanning function

Mapping surface scanning allows for the use of controlled grid modes to explore the entire sample surface.Omega/Theta XRDIt is easy to accommodate an additional XY positioning platform at the top of the turntable. The sample surface can be scanned according to a user-defined grid. Due to the size of the X-ray spot on the sample, the small grid spacing is about 1 millimeter.

The drawing stage can be combined with Omega scanning to obtain crystal orientation patterns, or with swing curve measurement to obtain surface distortion patterns. Can provide software packages for display and analysis.

The mapping surface scanning function of crystals is a valuable tool for diagnosing quality issues that occur during crystal growth and manufacturing processes

Even in a single crystal, the crystal orientation can exhibit slight changes on the surface due to internal strain caused by lattice defects. Orderly grown films can also have an interesting in-plane orientation distribution.

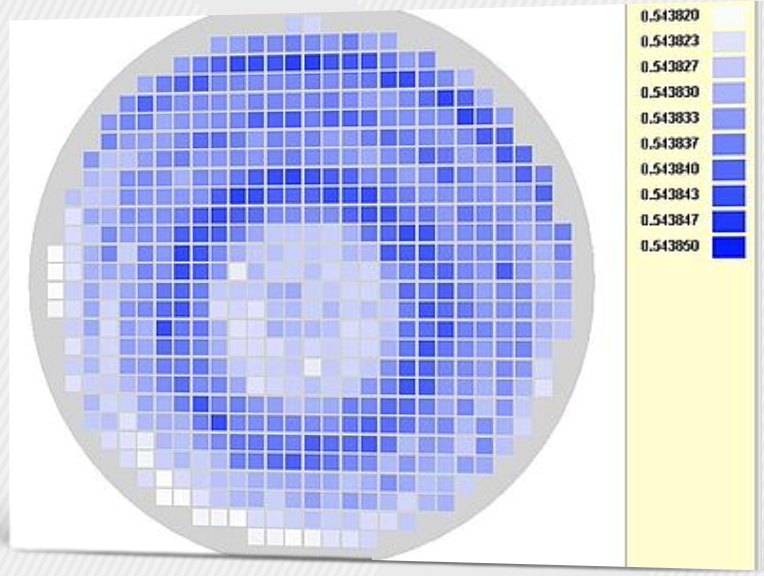

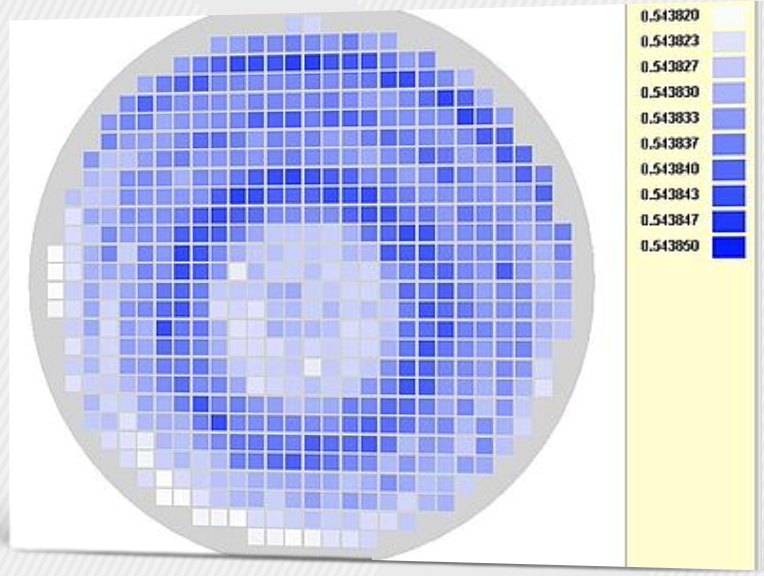

Drawing a surface requires a lot of measurement. Here, the Omega scanning method can provide its speed advantage. The orientation map shown in the figure is measured on a (Si, Ge) solid solution chip. The significant directional difference is 0.03 °. Concentric circles are arranged according to the growth rings of crystals.