The characteristics of SDCOM

Capable of measuring crystals as small as 1mm to or larger samples

Various sample racks and conveying fixtures, used for wire saws, polishing, etc

Side crystal direction marking option

Anhydrous cooling

**Accuracy: 0.01 ° (depending on crystal quality)

Determine the complete lattice orientation of a single crystal

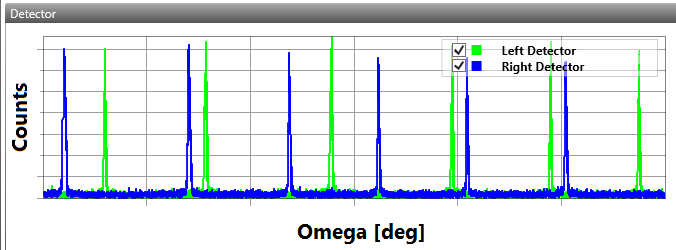

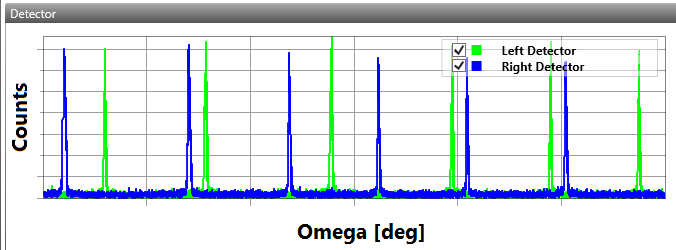

Ultra high speed crystal positioning measurement using Omega scanning method

Air cooled X-ray tube, no water cooling required

Suitable for research and production quality control

Manual operation (without automation options)

Marking and measurement of plane direction

- Omega scanning can determine the complete crystal orientation in one measurement. Therefore, the plane direction can be directly recognized. This is a useful feature to mark units or gaps in the plane direction or inspection direction.

- During the injection and lithography process of a wafer, a flat surface or groove serves as a positioning marker. After processing, the wafer carries hundreds of chips and needs to be separated by cutting.

- The chip must be correctly aligned with the lattice planes on the quasi crystal wafer that are easy to cut. Therefore, it is necessary to check the position of the platform or gap. To determine the position of a plane or gap, it is necessary to measure the components within the plane.

- This instrument can convert any plane direction to a specific position specified by the user by rotating the turntable. This simplifies the task of applying markers to specific plane directions, such as when a plane direction must be defined.

- For high throughput applications, an automatic measurement solution can be provided.

The direction of the crystal is determined by the reflection position

Suitable for multiple materials