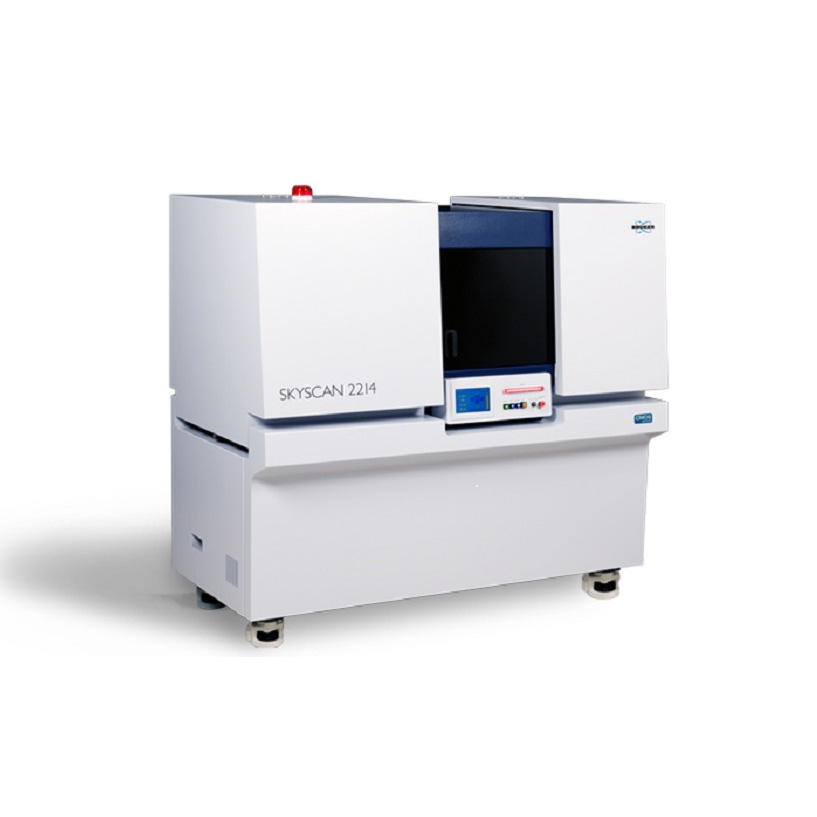

SKYSCAN 2214 CMOS Edition- Multi range nanoscale 3DXX-ray microscope

The multi-range nanoscale 3D X-ray microscope SKYSCAN 2214 CMOS covers a wide range of object sizes and spatial resolutions, enabling advanced 3D imaging and precise modeling of geological materials, composite materials, lithium batteries, fuel cells, electronic components, and in vitro preclinical applications such as lung imaging or * * vascularization in oil and gas exploration.

This instrument can scan and reconstruct the internal microstructure of objects with a diameter greater than 300 millimeters in 3D non-destructive testing, as well as perform sub micron level resolution on small samples.

In addition, the system is equipped with an "open" transmission X-ray source with a size of<0.5 microns and a diamond window. It can accommodate four X-ray detectors and has great flexibility. Automatic variable acquisition geometry and phase contrast enhancement can achieve excellent quality in a relatively short scanning time.

SKYSCAN 2214 CMOS will provide users with a complete set of 3D Suits software packages for free. This software suite covers all the functions required by users, including GPU accelerated reconstruction, 2D/3D morphological analysis, and surface and volume rendering visualization. And the software suite can be upgraded for free.

Main features:

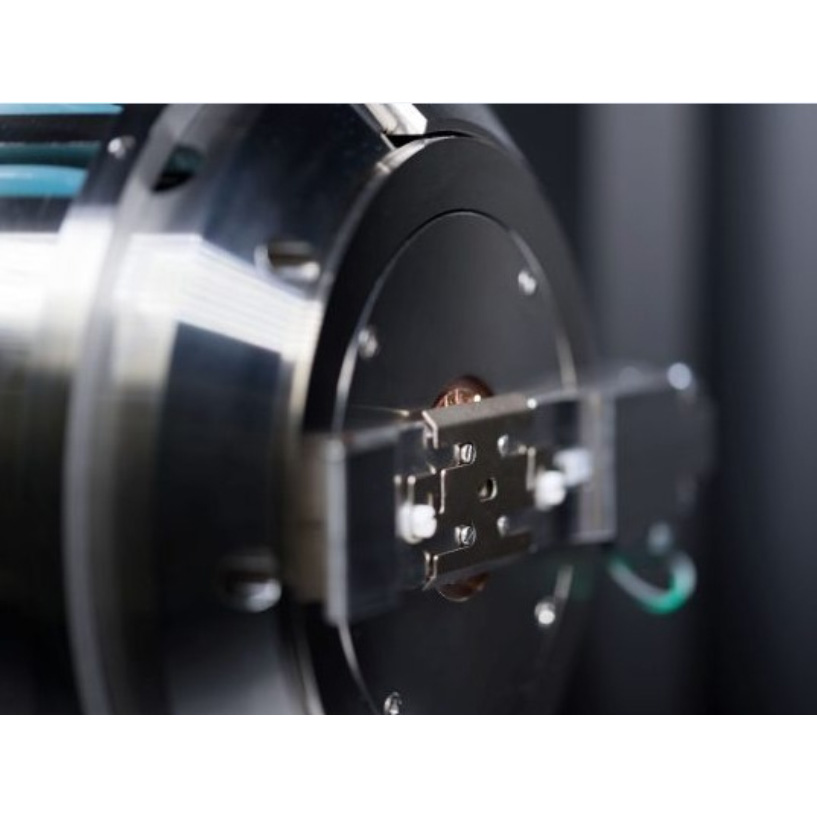

● X-ray light source

SKYSCAN 2214 adopts a new generation of open X-light sources. This light source can achieve actual spatial resolution better than 500 nm, up to 160 keV X-ray energy, and up to 16 W power. Due to its extremely simple pre registered filament replacement program, this light source requires almost no maintenance.

SKYSCAN 2214 features an open (pump type) nanofocal X-ray source with a diamond window. It can generate X-beams with peak energies ranging from 20 kV to 160 keV and provides two types of cathodes. Tungsten (W) cathode is suitable for a complete acceleration voltage range of up to 160 kV, with small spot sizes up to 800 nm. The LaB6 cathode is suitable for accelerating voltages from 20 kV to 100 kV, and the spot size of the X-ray beam can be less than 500 nm, ensuring high resolution in imaging and 3D reconstruction. The JIMA resolution test card shows that it can easily resolve structures up to 500 nm. In order to ensure the long-term stability of the focal spot size and the position of the emission source, the X light source can also be equipped with a water cooling system, which includes a circulation device that can accurately control the temperature of the cooling liquid to maintain temperature stability.

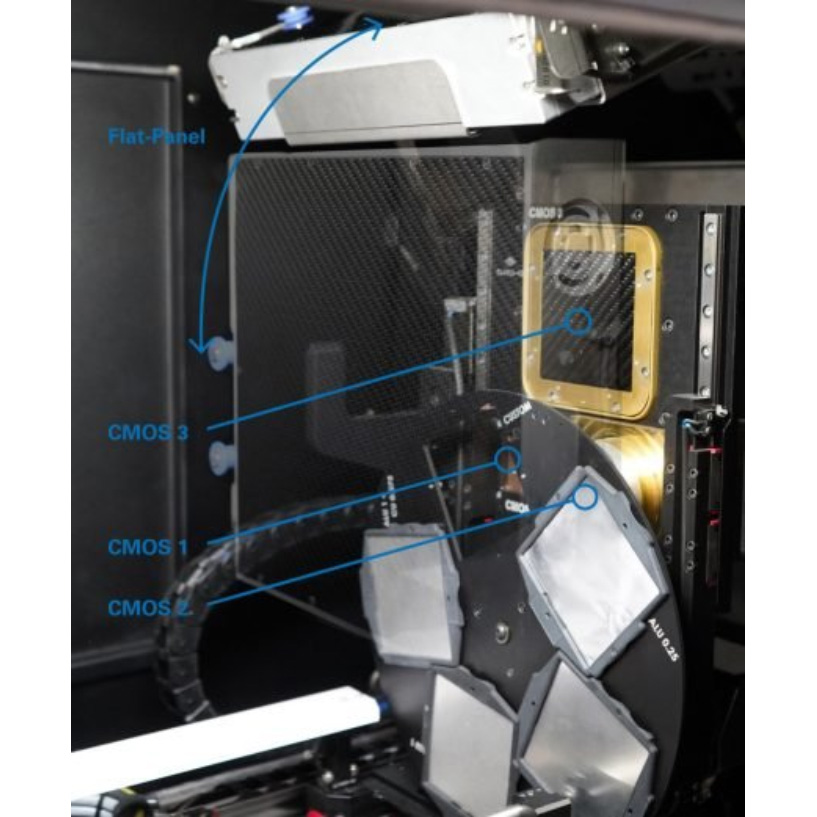

● Detectors

SKYSCAN 2214 can be equipped with four X-ray detectors for great flexibility: including three scientific and sCMOS detectors with different resolutions and field of view balance, as well as one flat panel detector to cover a super large field of view. Users only need to click the mouse to switch between detectors at will.

The use of small pixel large-sized CMOS detectors can extend high-resolution 3D imaging to large objects. The flexibility of the built-in detector allows it to adjust the field of view and spatial resolution based on the size and density of the object. Advanced reconstruction from the volume of interest, allowing for local high-resolution scanning of selected parts of large objects without affecting image quality.

In addition, by using offset detector positions and vertical object movement, the horizontal and vertical fields of view can be increased, respectively. Afterwards, 3D SUITE software automatically concatenates different images together and accurately compensates for offset and possible intensity differences.

With the development of research topics and analysis needs, detectors can be upgraded on-site at any time during the system's lifespan.