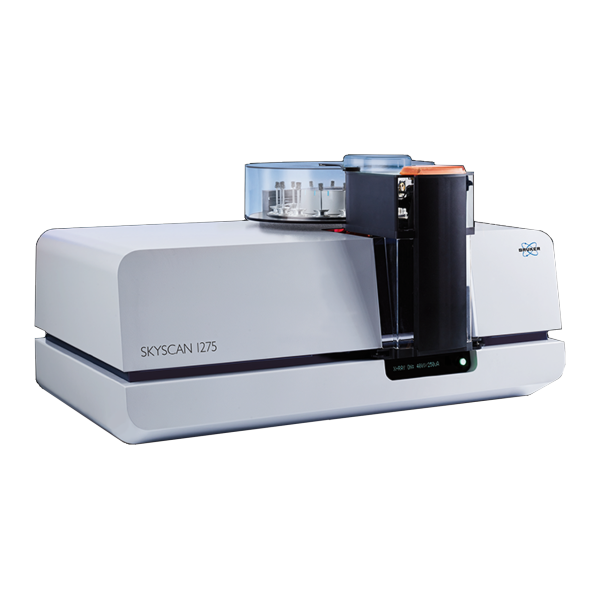

SKYSCAN 1275-3D XRM system suitable for everyone

The SKYSCAN 1275 desktop system is a true 3D X-ray microscopy imaging system designed for rapid scanning of different samples. Thanks to its compact geometric structure and fast flat panel detector, it only takes a few minutes to obtain results. This makes it an ideal choice for quality control and product testing.

SKYSCAN 1275 also has a high level of automation and excellent usability. Press the button on the control panel to initiate an automatic fast scan sequence, followed by reconstruction and volume rendering. All steps have also been completed when scanning the next sample.

The optional 16 bit automatic sampler can be used to achieve unmanned high-throughput scanning.

SKYSCAN 1275 has 3D SUITE supporting software. This comprehensive software package includes GPU accelerated reconstruction, 2D/3D morphology analysis, and surface and volume rendering visualization.

Main features:

XRM for button operation

·Simply manually or automatically insert the sample without any further intervention to obtain a complete 3D volume map.

·The button operated XRM includes all functions: automatic sample size detection, sample scanning, 3D reconstruction, and 3D volume rendering. Suitable for performing routine analytical tasks and also suitable for non professional users.

·Do you need complete control? No problem, SKYSCAN 1275 has all the functions.After being equipped with a sample switcher, SKYSCAN 1275 can operate 24/7 without interruption.

Automatic sampler

·SKYSCAN 1275 can be equipped with an external automatic injection system with 16 positions to improve quality control and processing speed during routine analysis.

·The automatic sampler can accommodate samples of different sizes, with a maximum sample diameter limit of 96 mm.

·You can easily switch samples at any time without interrupting the ongoing scanning process. The system can automatically detect new samples, and the LED can display the status of each scan: prepared, scanned, and completed.

In situ testing bench

·Brooke's material testing platform can perform compression tests with an upper limit of 4400 N and tensile tests with an upper limit of 440 N. All test benches can be automatically connected together through the system's rotary table without the need for any external cables. By using the provided software, a scheduled scanning test can be set up.

·Brooke's heating and cooling tables can reach an upper limit of 80 º C or a bottom line temperature 30 º C lower than the ambient temperature. Like other test benches, the heating and cooling benches do not require any additional connections, and the system can automatically identify different test benches.

·By using heating and cooling stages, samples can be tested under non environmental conditions to evaluate the effect of temperature on the microstructure of the samples.