Specially designed for outstanding desktop metrology

Brooke's proprietary optical head tilt/pitch technology provides users with great flexibility in production settings and testing. Brooke combines the automatic tilt/tilt function with the optical path in the microscope lens, achieving the integration of detection points and line of sight without being affected by tilt, thereby reducing operator intervention and providing maximum reproducibility. Other hardware features include innovative workbench design that can enhance splicing capabilities; Equipped with a 5MP camera and a 1200x1000 measurement array, it can reduce noise, expand field of view, and improve lateral resolution. The ContourX-500 integrates these functions with automated platform settings and objective lenses, and occupies only a small space, making it an ideal system for on-demand measurement research and industrial metrology.

The traditional pitch rolling workbench design requires operators to adjust five rotation axes to keep the detection points in line of sight for measurement. Brooke's unique optical head tilt/tilt design, unaffected by tilt, can keep the line of sight at the detection point, optimizing image acquisition and significantly reducing data acquisition time.

Directly using multiple analyses

ContourX-500 adopts Brooke's simple yet powerful VisionXpress ™ And Vision64 ® User interface, providing thousands of custom analyses to improve the efficiency of laboratories and factories. Brooke's new Universal Scanning Interferometry (USI) measurement mode provides fully automatic, self sensing surface texture, optimized signal processing, and performs the most accurate and practical calculations on the analyzed surface morphology.

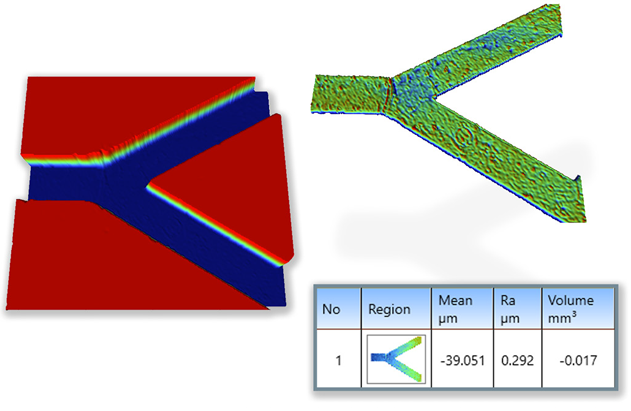

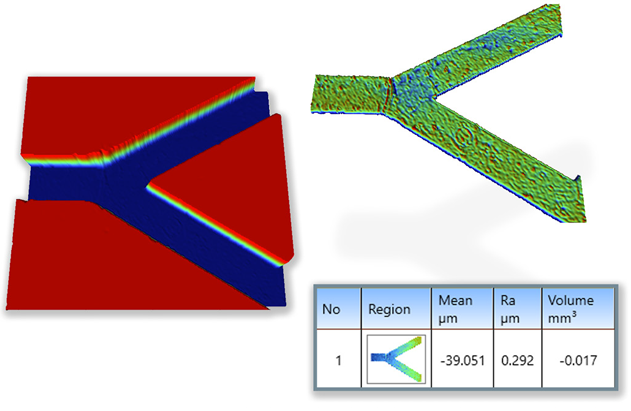

Analyze the bottom channels of microfluidic devices and extract them directly from multiple regions of Vision64.