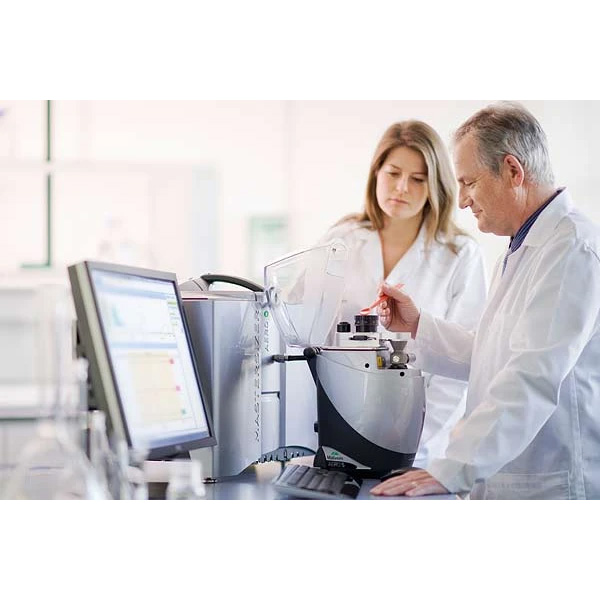

Laser particle size analyzer

The Mastersizer 3000 laser diffraction particle size analyzer can provide fast and convenient particle size distribution testing for dry and wet dispersion. This laser particle size analyzer can measure particles in the range of nanometers to millimeters, with a compact size and stable and reliable performance, providing measurements for all users without the need for operator intervention. Marvin Panaco brings technology, applications, and various solutions to Mastersizer users from over 10000 companies around the world in the field of granularity analysis.